Harrisons automotive lint free wipes make every stage of vehicle manufacturing and maintenance cleaner, faster, and more effective. From surface prep with our automotive panel wipes and automotive tack cloths to final polish, our range of solvent-resistant wipes and heavy duty lint free cloths will help you work efficiently and achieve professional results every time.

The Harrisons Industrial Range will help you find the perfect wipe for your process, so you can keep your operations running.

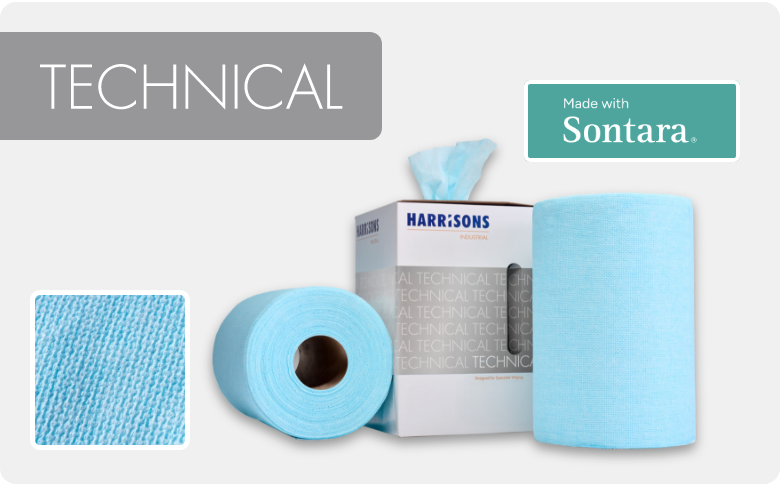

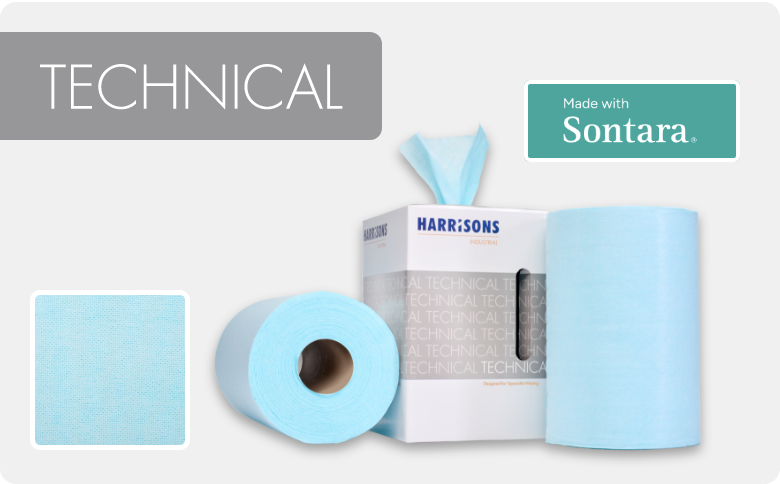

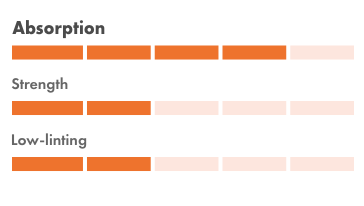

Speak to an expertHarrisons’ Technical wipes guarantee you achieve the very highest cleaning standards. Coming in fuller sizes and designed for precision, these specialist wipes are our largest and can handle cleaning tasks in industries where there is no room for failure.

Made from Sontara® materials, renowned for their proprietary technology that delivers unrivalled performance, these wipes use no binders, chemicals, or adhesives.

Sontara®’s unique hydroentangling process uses high-pressure water jets to weave the fibres together, bringing maximum strength, hyper absorbency, and ultra low-linting properties.

A plastic free wipe delivering hyper absorbency and sustainability.

View product

Order a sample

View product

Order a sample

Ultra durable and tear resistant, this wipe is ideal for degreasing and solvent-wiping.

View product

Order a sample

View product

Order a sample

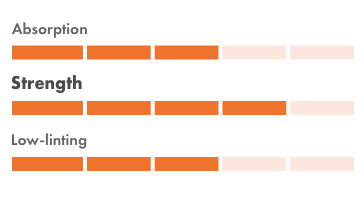

Raise your cleaning standards with our Premium wipes. Engineered for tasks that require a tougher approach, they offer extra strength and high absorbency, making them ideal for tackling grease, oil, and dirt. Harrisons’ Premium wipes offer great performance and value.

A plastic free, sustainable wipe with high absorbency for delicate surfaces.

View product

Order a sample

View product

Order a sample

An extra strong choice when wet or dry for medium-duty cleaning.

View product

Order a sample

View product

Order a sample

Our heaviest-duty wipe, this is the durable choice for solvent-resistant cleaning.

View product

Order a sample

View product

Order a sample

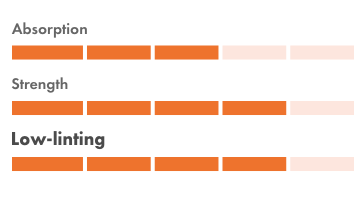

Created with over a century of expertise, our Pro wipes offer reliable, affordable cleaning solutions for your daily cleaning needs.

These versatile wipes tackle light and moderate-duty cleaning tasks with ease, from wiping down tools to cleaning workstations.

Whether you’re in manufacturing, engineering, or maintenance, Harrisons’ Pro wipes are your go-to choice for efficient and cost-effective cleaning.

A cost-effective & low-linting wipe. Ideal for paper replacement.

View product

Order a sample

View product

Order a sample

Learn how we’ve helped automotive businesses save time and money with the perfect wiping solution.

A specialist in driving surface preparation needed a high-performance, cost-effective wipe to replace a wipe that it had used for many years, but had become too expensive. After testing the product, our experts were able to provide an alternative that delivered the same results while reducing costs.

To tackle storage constraints, we also designed a tailored delivery system, ensuring a steady supply at all times.

The result? Cost savings without compromising product quality.

A key distributor came to us with a challenge at the UK’s largest bus manufacturing site. Their customer needed a wipe for glass prep – one that performed just as well as their current solution, but delivered better value. The existing supplier couldn’t meet the brief.

We worked closely with the distributor to assess volumes, margins, and application needs. After conducting product trials and a site survey, we recommended a wipe that not only hit performance targets, it also delivered a £50,000 cost savings.

A great result for the distributor, a big win for the manufacturer, and proof that with Harrisons expertise, cost and quality don’t have to be a trade-off.

After facing price rises, we were approached by the distributor of a major caravan manufacturer looking to find a new wiping solution. After visiting the site, our experts learned that the manufacturer needed a tough, low-linting wipe for final cleaning that wouldn’t break down when saturated – a task their previous wipes struggled with.

With Harrisons’ expert advice, the distributor introduced a more durable Harrisons wipe and demonstrated its performance and cost savings in use.

Impressed by the results, the manufacturer made the switch, and has stuck with Harrisons ever since.

A specialist in driving surface preparation needed a high-performance, cost-effective wipe to replace a wipe that it had used for many years, but had become too expensive. After testing the product, our experts were able to provide an alternative that delivered the same results while reducing costs.

To tackle storage constraints, we also designed a tailored delivery system, ensuring a steady supply at all times.

The result? Cost savings without compromising product quality.

A key distributor came to us with a challenge at the UK’s largest bus manufacturing site. Their customer needed a wipe for glass prep – one that performed just as well as their current solution, but delivered better value. The existing supplier couldn’t meet the brief.

We worked closely with the distributor to assess volumes, margins, and application needs. After conducting product trials and a site survey, we recommended a wipe that not only hit performance targets, it also delivered a £50,000 cost savings.

A great result for the distributor, a big win for the manufacturer, and proof that with Harrisons expertise, cost and quality don’t have to be a trade-off.

After facing price rises, we were approached by the distributor of a major caravan manufacturer looking to find a new wiping solution. After visiting the site, our experts learned that the manufacturer needed a tough, low-linting wipe for final cleaning that wouldn’t break down when saturated – a task their previous wipes struggled with.

With Harrisons’ expert advice, the distributor introduced a more durable Harrisons wipe and demonstrated its performance and cost savings in use.

Impressed by the results, the manufacturer made the switch, and has stuck with Harrisons ever since.

In car factories, every task demands precision, from sealing panels to polishing finishes. Our range of automotive panel wipes, automotive tack cloths, and automotive lint free wipes are engineered for specific applications, ensuring consistency, efficiency, and flawless results. Whether it’s solvent resistant wipes for automotive refinishing or heavy duty lint free cloths for automotive assembly, our solutions are designed to save time, cut waste, and maintain the highest standards at every stage of production.

Proper sealant application relies on clean, debris-free surfaces. Harrisons’ automotive panel wipes remove excess sealant quickly without leaving fibres, ensuring smooth, even bonds. This reduces rework, improves adhesion, and speeds up your workflow.

Harrisons’ solvent resistant wipes for automotive refinishing tackle grease, oils, and residues safely, making solvent wiping faster and more effective. Their durability and absorbency control solvent use while protecting surfaces, boosting both efficiency and safety.

Switching to Harrisons’ automotive lint free wipes supports sustainable practices without compromising performance. Highly durable and reusable for multiple tasks, they reduce waste, maintain cleanliness, and help businesses achieve greener, more efficient operations.

Dust and particles can ruin finishes if not removed properly. Harrisons’ tack wipes pick up contaminants from critical surfaces, leaving them clean and ready for painting or coating, while saving time and improving overall surface quality.

Achieve a high-quality finish with Harrisons’ automotive lint free wipes for perfect surface prep. They remove polishing residues, buff to a smooth shine, and prevent streaking, helping you reach professional results faster and more consistently.

Sensitive surfaces demand wipes that won’t shed fibres. Harrisons’ heavy duty lint free cloths for automotive assembly protect coatings, glass, and instruments from contamination, supporting precision work and reducing the risk of defects.

Clean glass and critical surfaces efficiently with Harrisons’ automotive lint free wipes. Their absorbency and lint-free design leave surfaces spotless, enhancing visibility, surface prep, and overall safety.

Harrisons’ solvent resistant wipes for automotive refinishing help manage solvent use by absorbing liquids effectively, reducing waste and exposure. This not only improves cost efficiency but also supports safer, cleaner industrial processes.

If you want to explore how Harrisons can help your business improve with our range of automotive wipes, speak to one of our experts today!

Contact usWhat makes Harrisons automotive wipes different from regular shop towels

Harrisons wipes are specially designed as solvent resistant wipes for automotive refinishing, providing superior strength and reliability compared with regular shop towels. Standard towels often leave fibres behind or break down when exposed to chemicals, which can compromise automotive panel wipe performance and lead to rework. Using Harrisons wipes ensures vehicle surfaces are properly cleaned, prepped, and maintained, helping workshops achieve a flawless finish efficiently while saving time and reducing contamination risks.

Can Harrisons wipes be used with all types of automotive solvents?

Yes. Our solvent resistant wipes for automotive refinishing are engineered to withstand exposure to degreasers, cleaning solutions, and other chemicals commonly used in workshops. They won’t leave fibres or residues, making them ideal for automotive panel wipe tasks, tack wipes, and general mechanical cleaning. Using Harrisons wipes allows professionals to maintain clean surfaces, reduce errors, and streamline workflows in both detailing and assembly processes.

What are automotive tack wipes, and how do they help in finishing?

Automotive tack wipes, often referred to as automotive tack cloth, are specially designed automotive tack wipes that remove fine dust, lint, and debris from surfaces before painting or coating. Unlike standard cloths, these wipes are lint-free and leave no residues, ensuring that finishes adhere perfectly and remain flawless. Using automotive tack cloth reduces the risk of imperfections such as bubbling, uneven coatings, or surface blemishes, helping professionals achieve a smooth, high-quality finish while saving time on rework.

Are these wipes suitable for polishing and finishing?

Absolutely. Harrisons automotive lint free wipes are perfect for polishing, waxing, and finishing surfaces. Unlike standard cloths, they leave no fibres or streaks, helping achieve a high-gloss, flawless finish. Whether used as automotive tack cloth or for final buffing, these wipes make it easy to remove residues efficiently, saving time and ensuring consistent professional results every time.

How do Harrisons automotive wipes improve efficiency in the workshop?

Using heavy duty lint free cloths for automotive assembly and vehicle cleaning wipes saves time and reduces mistakes. Their strength, lint-free design, and chemical resistance mean fewer replacements, less contamination, and reduced surface rework. This allows professionals to prep, clean, and polish surfaces faster while maintaining high-quality standards across all automotive refinishing and assembly tasks.

Can these wipes help prevent defects in paint and coatings?

Yes. Proper automotive panel wipe preparation is critical to avoiding defects like bubbling, peeling, or uneven finishes. Our solvent resistant wipes for automotive refinishing remove oils, dust, and contaminants that could affect adhesion, ensuring coatings bond properly and surfaces achieve a flawless appearance. This reduces wasted materials, avoids rework, and keeps workshops running efficiently.

Are Harrisons wipes environmentally friendly?

Harrisons automotive wipes are designed with sustainability in mind. They’re durable enough to minimise waste, meaning fewer wipes are used per job, and their chemical resistance ensures effective cleaning without excess solvent use.

The Prem 100 and Tech 100 wipes are 100% plastic free and compostable, making them the most sustainable products in our range. Using these wipes supports eco-conscious automotive assembly and refinishing practices while maintaining high cleaning standards.

Can Harrisons wipes be used on delicate surfaces like glass?

Yes. Our automotive lint free wipes are safe for delicate and critical surfaces, including glass, painted panels, and interior trims. Their lint-free construction prevents scratches and leaves no fibres behind, making them ideal for finishing tasks and automotive tack cloth applications where precision and cleanliness are essential.