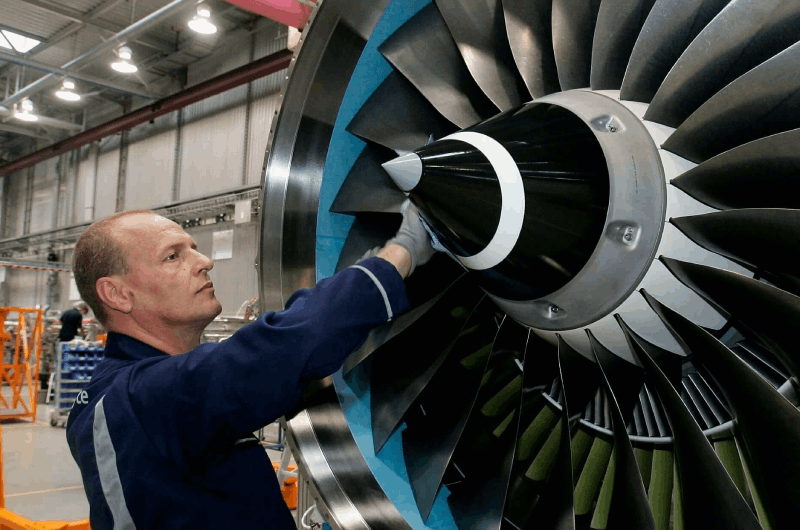

In aerospace, attention to detail is everything. From surface prep to final finishing, the industry demands cleaning solutions that deliver consistency, safety, and compliance every time. That’s why Harrisons supplies aerospace wipes designed for manufacturers, MRO providers, and operators who can’t afford to compromise.

Whether you need AMS approved aerospace grade wipes, or you’re looking to find the perfect wipe for your process with the Harrisons Industrial Range – our wipes guarantee a high performance clean for the aerospace sector.

Speak to an expertHarrisons’ Technical wipes guarantee you achieve the very highest cleaning standards. Coming in fuller sizes and designed for precision, these specialist wipes are our largest and can handle cleaning tasks in industries where there is no room for failure.

Made from Sontara® materials, renowned for their proprietary technology that delivers unrivalled performance, these wipes use no binders, chemicals, or adhesives.

Sontara®’s unique hydroentangling process uses high-pressure water jets to weave the fibres together, bringing maximum strength, hyper absorbency, and ultra low-linting properties.

Raise your cleaning standards with our Premium wipes. Engineered for tasks that require a tougher approach, they offer extra strength and high absorbency, making them ideal for tackling grease, oil, and dirt. Harrisons’ Premium wipes offer great performance and value.

Created with over a century of expertise, our Pro wipes offer reliable, affordable cleaning solutions for your daily cleaning needs.

These versatile wipes tackle light and moderate-duty cleaning tasks with ease, from wiping down tools to cleaning workstations.

Whether you’re in manufacturing, engineering, or maintenance, Harrisons’ Pro wipes are your go-to choice for efficient and cost-effective cleaning.

Learn how we’ve helped aerospace businesses save time and money with the perfect wiping solution.

After looking for ways to cut costs, a blue-chip British aviation and defence firm asked Harrisons to review its wiping processes.

A site survey revealed ineffective blue roll wasting days on clean downs and failing to protect staff.

Harrisons introduced the PRO 300, instantly transforming results — cutting cleaning time in half, raising site standards, and delivering £53k in savings.

An aerospace MRO provider faced issues with lint contamination, snagging, and clutter due to using rags in maintenance. Harrisons introduced two trial solutions, offering a cleaner, more efficient alternative.

After testing, they saw immediate benefits — our dispenser box system reduced clutter, and the wipes provided superior performance. Best of all, the switch is now saving them £7,000 annually.

A major UK airline needed a sustainable alternative to its existing wipes for cleaning aircraft, tools, and machinery. Harrisons supplied a binder-free, 100% compostable wipe that would be perfect for their daily wiping tasks.

After successful trials at two sites, the airline was impressed by the wipes’ residue-free performance and the improved workspace efficiency due to our dispenser boxes. Now, they are preparing for a UK-wide rollout, reinforcing their commitment to sustainability.

After looking for ways to cut costs, a blue-chip British aviation and defence firm asked Harrisons to review its wiping processes.

A site survey revealed ineffective blue roll wasting days on clean downs and failing to protect staff.

Harrisons introduced the PRO 300, instantly transforming results — cutting cleaning time in half, raising site standards, and delivering £53k in savings.

An aerospace MRO provider faced issues with lint contamination, snagging, and clutter due to using rags in maintenance. Harrisons introduced two trial solutions, offering a cleaner, more efficient alternative.

After testing, they saw immediate benefits — our dispenser box system reduced clutter, and the wipes provided superior performance. Best of all, the switch is now saving them £7,000 annually.

A major UK airline needed a sustainable alternative to its existing wipes for cleaning aircraft, tools, and machinery. Harrisons supplied a binder-free, 100% compostable wipe that would be perfect for their daily wiping tasks.

After successful trials at two sites, the airline was impressed by the wipes’ residue-free performance and the improved workspace efficiency due to our dispenser boxes. Now, they are preparing for a UK-wide rollout, reinforcing their commitment to sustainability.

In a sector as tightly regulated as aerospace, precision cleaning is essential. Harrisons’ wipes are engineered for aerospace cleaning processes that demand safety, reliability, and compliance. Explore our range of wipes designed for every stage of aerospace maintenance and manufacturing.

Harrisons’ aerospace cleaning products help you manage solvent use more effectively. Our solvent-resistant aerospace wipes reduce waste and operator exposure, ensuring safer, more sustainable cleaning while maintaining performance.

Switching to sustainable aerospace wipes supports greener practices without compromising results. Durable and plastic-free, the Tech 100 and Prem 100 cut waste and help operators meet sustainability targets while keeping aircraft and equipment spotless.

Sensitive aerospace components demand precision. Our low-lint wipes for aerospace maintenance protect delicate surfaces, instruments, and coatings from contamination, reducing the risk of costly rework or safety issues.

Meeting industry standards is non-negotiable. We can supply aerospace grade wipes that are AMS-approved and engineered to deliver safe, compliant cleaning performance across the most demanding aerospace applications.

For degreasing and removing oils or residues, our best nonwoven wipes for aerospace parts deliver durability, absorbency, and solvent resistance. They tackle contamination quickly while protecting critical surfaces.

Dust and particles can ruin finishes and damage equipment. Harrisons’ aerospace tack cloths remove contaminants from critical surfaces before painting or coating, ensuring flawless results and reducing the risk of defects.

Clean glass and critical surfaces efficiently with Harrisons’ automotive lint free wipes. Their absorbency and lint-free design leave surfaces spotless, enhancing visibility, surface prep, and overall safety.

For surface prep and finishing, our lint-free aerospace wipes remove residues and polish surfaces to a smooth, streak-free shine — speeding up workflows and improving finish quality.

From cockpit windows to instrumentation, our aerospace cleaning products ensure glass and sensitive surfaces are cleaned efficiently. Highly absorbent and lint-free, they leave no streaks or residues.

Proper preparation underpins every aerospace process. Our wipes remove debris, grease, and residue, ensuring surfaces are ready for bonding, coating, or sealing, reducing rework and saving time.

Final detailing requires precision. Harrisons’ low-lint aerospace wipes deliver consistent results during finishing tasks, ensuring parts and equipment meet the highest quality standards.

Harrisons has been supporting manufacturers with high-grade aerospace wipes for decades. We work with the very best in industry to introduce wiping processes that deliver results. From sustainability to efficiency, our products are leading the way.

Efficiency and precision matter during maintenance, repair and overhaul. Our high-performance wipes are trusted across the aerospace sector to consistent results for all wiping tasks, including surface prep, cleaning, and finishing. This means fewer faults, lower turnaround times, and a smoother operation.

If you’re ready to improve the way you wipe, speak to one of our experts today to learn more about our aerospace wipes range.

Contact usWhy are aerospace wipes different from standard industrial wipes?

Aerospace wipes are engineered to meet strict industry regulations where safety and consistency are non-negotiable. Unlike general industrial wipes, they are low-lint, solvent resistant, and often comply with specifications such as AMS 3819 Class 2 Grade A wipes or BMS 15-5F wipes. This ensures they won’t contaminate sensitive components, coatings, or bonded joints, helping to maintain airworthiness and compliance.

What happens if I use the wrong wipes in aerospace maintenance?

Using unsuitable wipes can lead to serious issues such as lint contamination, bonding failures, or chemical incompatibility with solvents and coatings. In aerospace, this risks both regulatory non-compliance and costly rework. The right aerospace solvent resistant wipes not only ensure cleaning effectiveness but also protect both surfaces and workers.

What are the best nonwoven wipes for aerospace parts?

The best nonwoven wipes for aerospace parts are those combining high absorbency, strength, and ultra-low linting properties. Options such as Harrisons’ Technical and Premium ranges and market-proven solutions like Chicopee VeraClean aerospace wipes are specifically designed to withstand demanding surface preparation and finishing tasks while leaving no residue behind.

Do I need AMS-approved wipes?

In most cases, yes. Standards such as AMS 3819 Class 2 Grade A wipes and BMS 15-5F wipes exist to guarantee wipes are safe and effective for aerospace use. By choosing aerospace grade wipes that meet these requirements, you eliminate variability, achieve compliance, and reduce the risks associated with untested or non-certified products.

How do aerospace tack cloths improve finishing?

Aerospace tack cloths are specially treated to capture fine dust and particles that can ruin coatings or paint finishes. By ensuring surfaces are contaminant-free before application, these wipes enhance adhesion, reduce rework, and improve overall surface quality. In processes such as surface preparation, tack wipes are often the last line of defence against defects.

Are sustainable wipes suitable for aerospace applications?

Yes, but only if they are carefully engineered. The Tech 100 and Prem 100 sustainable wipes are made with plastic-free materials that deliver the same cleaning strength and absorbency as conventional wipes. The Tech 100 and Prem 100 are compostable too, helping operators align with sustainability targets without compromising performance.

Can aerospace wipes be used in cleanroom environments?

Some aerospace operations require controlled environments, particularly when assembling or maintaining high-value components. For these tasks, ISO cleanroom wipes for aerospace are the right choice, as they are designed to minimise particle generation and chemical contamination while maintaining consistent performance.

What’s the difference between general solvent wipes and aerospace solvent resistant wipes?

While general-purpose solvent wipes can break down under exposure, aerospace solvent resistant wipes are engineered to handle aggressive cleaning chemicals without tearing, shredding, or leaching binders. This makes them essential for degreasing, paint preparation, and critical cleaning in aerospace environments.